table of contents

- What is Acryloyl Chloride?

- Key Challenges in Loading and Handling Acryloyl Chloride

- Step-by-Step Guide to Safe Loading of Acryloyl Chloride

- Safety Assessments and Planning

- Personnel Safety

- Equipment Check

- Pre-loading Procedures

- Sealing and Inspection

- Loading Process

- Safe Transport and Storage of Acryloyl Chloride

- Conclusion

What is Acryloyl Chloride?

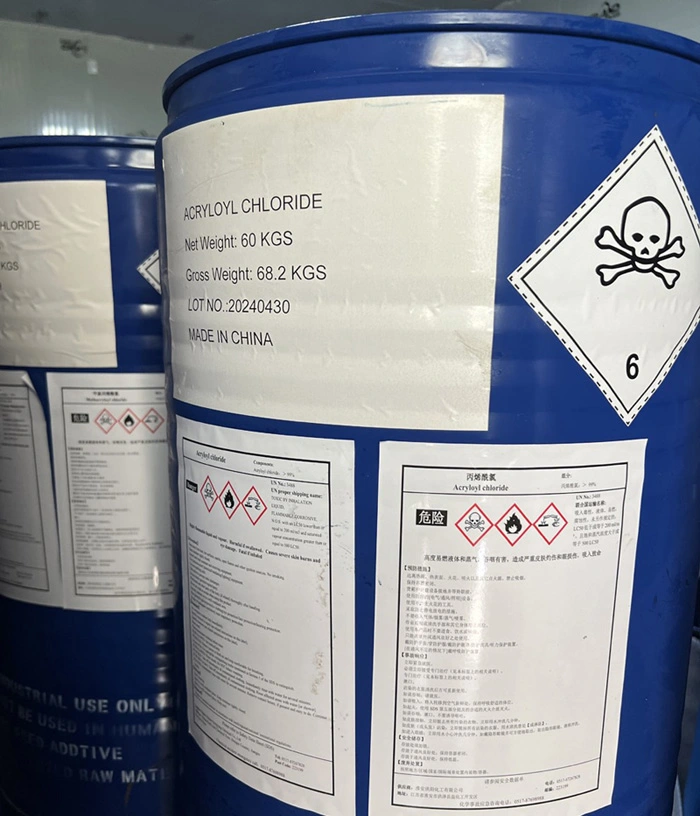

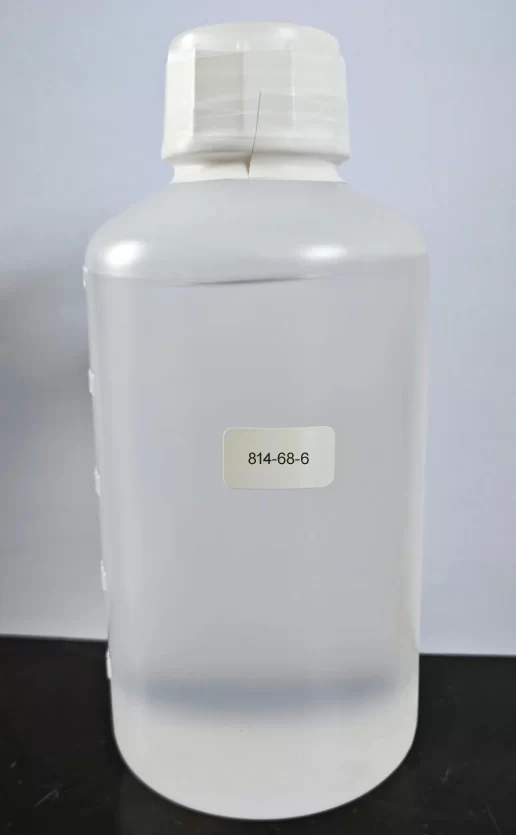

Acryloyl chloride (CH2=CHCOCl) Cas No.: 814-68-6 is a colorless liquid with a pungent odor. It is known for its high reactivity, especially with water, which makes it both a valuable industrial chemical and a significant safety hazard. Its primary applications include:

- Polymer Synthesis: Used in producing acrylic polymers and resins.

- Pharmaceuticals: Acts as a reagent in the synthesis of various pharmaceuticals.

- Specialty Chemicals: Used in the manufacture of dyes, adhesives, and coatings.

Due to its reactivity, acryloyl chloride must be handled with extreme care to prevent accidents and ensure safe usage.

Key Challenges in Loading and Handling Acryloyl Chloride

Handling acryloyl chloride presents several challenges:

- High Reactivity: Reacts violently with water and many other substances.

- Corrosiveness: Highly corrosive to skin, eyes, and respiratory tract.

- Toxicity: Hazardous by inhalation, ingestion, and skin absorption.

- Environmental Impact: Can cause significant environmental damage if released.

Given these risks, it’s crucial to follow comprehensive safety protocols when loading and handling this chemical.

Step-by-Step Guide to Safe Loading of Acryloyl Chloride

Safety Assessments and Planning

- Risk Assessment: Identify potential hazards and ensure mitigation strategies are in place.

- Review Safety Data Sheets (SDS): Understand the chemical properties, hazards, and emergency procedures.

- Emergency Procedures: Develop and train staff on emergency response plans.

Personnel Safety

- Training: Ensure all personnel are trained in handling hazardous chemicals.

- Personal Protective Equipment (PPE): Use chemical-resistant gloves, goggles, face shields, and suits.

Equipment Check

- Inspection: Check containers for integrity and ensure they are clean and dry.

- Compatibility: Use containers made of materials resistant to acids and bases, like stainless steel or specific plastics.

Pre-loading Procedures

Sealing and Inspection

- Secure Sealing: Ensure all package are tightly sealed.

- Inspection: Check the package for leaks or damage before loading.

- Labeling: Clearly mark containers with hazard symbols and handling instructions.

Loading Process

- Loading Area set up: Keep the loading area well ventilated.

- Temperature Monitoring: Maintain storage temperatures within safe limits.

- Moisture Control: Keep the environment dry and consider nitrogen purging to displace moisture.

- Closed Package Transfer: Use closed package like steel-plastic drum to minimize exposure.

- Monitoring During Loading: Watch for leaks, pressure changes, and temperature fluctuations.

Safe Transport and Storage of Acryloyl Chloride

Regulatory Compliance: Adhere to transportation regulations for hazardous materials.

Secure Transport: Use well-marked, secure vehicles to transport containers.

Storage Conditions: Keep containers in a cool, dry, and ventilated area, away from incompatible substances.

Regular Inspection: Inspect storage areas regularly to ensure safety measures are maintained.

Conclusion

Handling acryloyl chloride requires meticulous planning and adherence to strict safety protocols due to its highly reactive and hazardous nature. And by following the steps outlined above, you can mitigate the risks and ensure safe operations. So always prioritize safety and stay informed about the latest handling procedures and regulations to protect both personnel and the environment.